Fleet Management And Maintenance Blog

LATEST ARTICLES

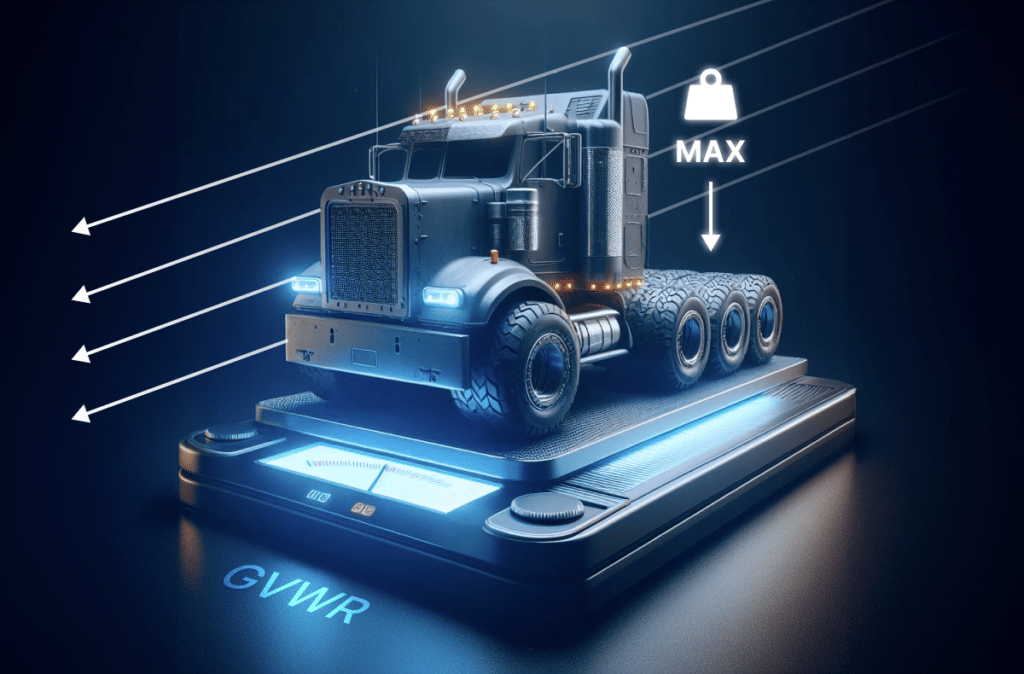

What Is Maximum Payload Capacity And How To Calculate It

When you’re gearing up for a heavy-duty haul, understanding your vehicle’s maximum payload capacity is paramount. But what exactly is maximum payload capacity, and how

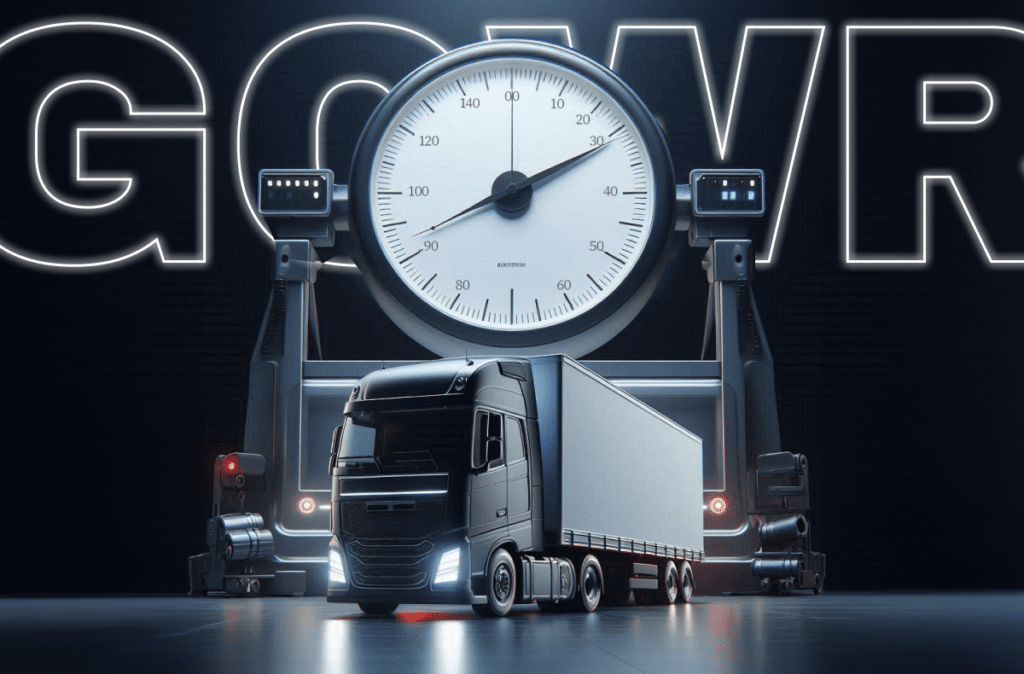

What is Gross Combined Weight Rating

Fleet-related weight metrics are at the heart of running a safe and efficient fleet operation, no matter how big your fleet is. Among other essential

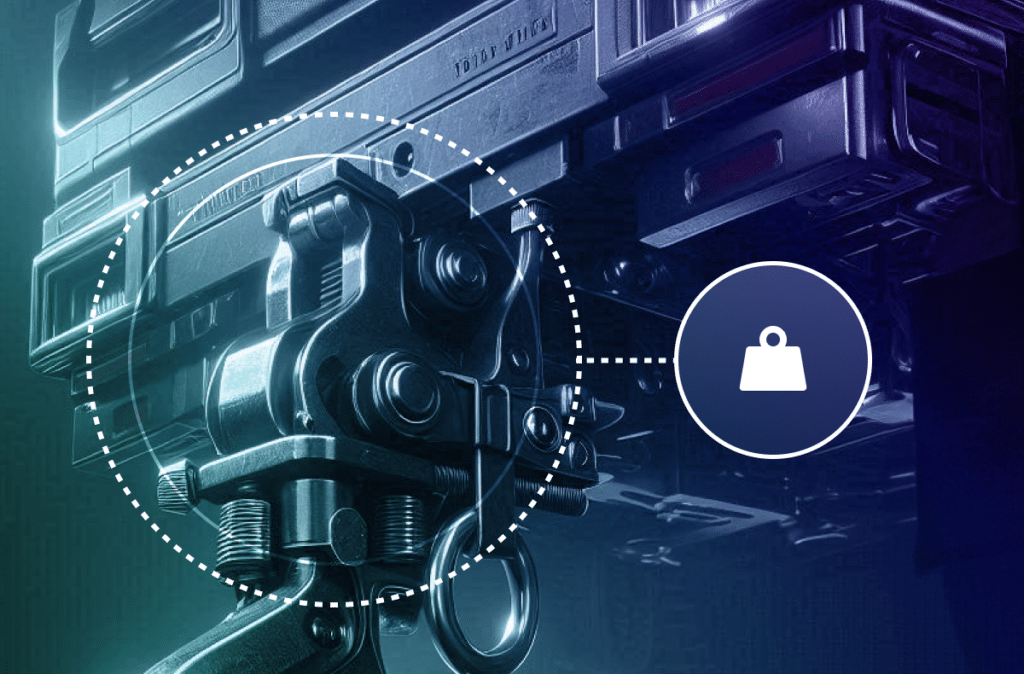

What Is Tongue Weight And How To Measure It

Regardless of the size of your fleet, chances are that you operate with trailers for part of your business processes. In order to ensure the

What Does Deadhead Mean In Trucking? Definition, Cons And Prevention

The logistics industry consists of a wide array of different sub-topics, metrics, and processes to keep in mind as a fleet manager. However, one of

Vehicle Dry Weight Explained

Among other weight metrics related to fleet management, vehicle dry weight stands out as an essential factor for making strategic decisions as a fleet manager

Fleet Sustainability Core Principles

In today’s world, sustainability is no longer just a buzzword but a guiding principle for businesses across industries. For fleet businesses, adopting sustainable fleet management